Published on 12/12/2024

A guide to bucket maintenance - Extend the life of your tools with the CFUS method!

At ACB+, we are committed to supporting you in the choice and durability of your equipment. Proper, regular maintenance is essential to guaranteeing the performance of your buckets, extending their service life, and maintaining safety on your worksites. Discover our maintenance tips, based on best practices and recommendations from our product manuals.

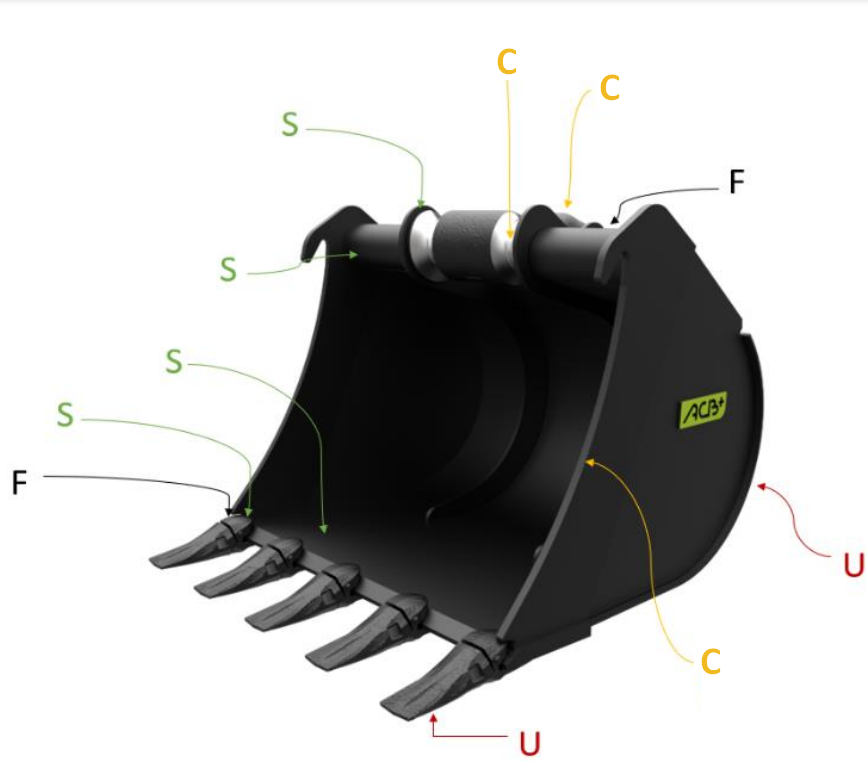

C for Cleanliness

C for Cleanliness F for Fixing

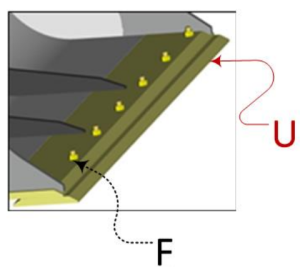

F for Fixing

U for Usury

U for Usury S for Solder

S for Solder