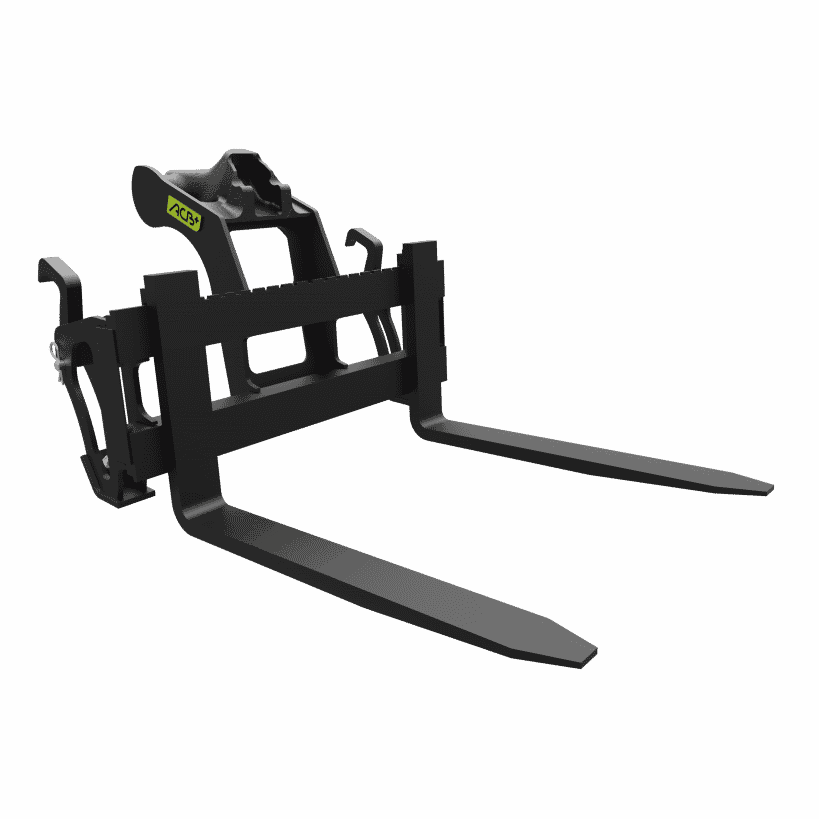

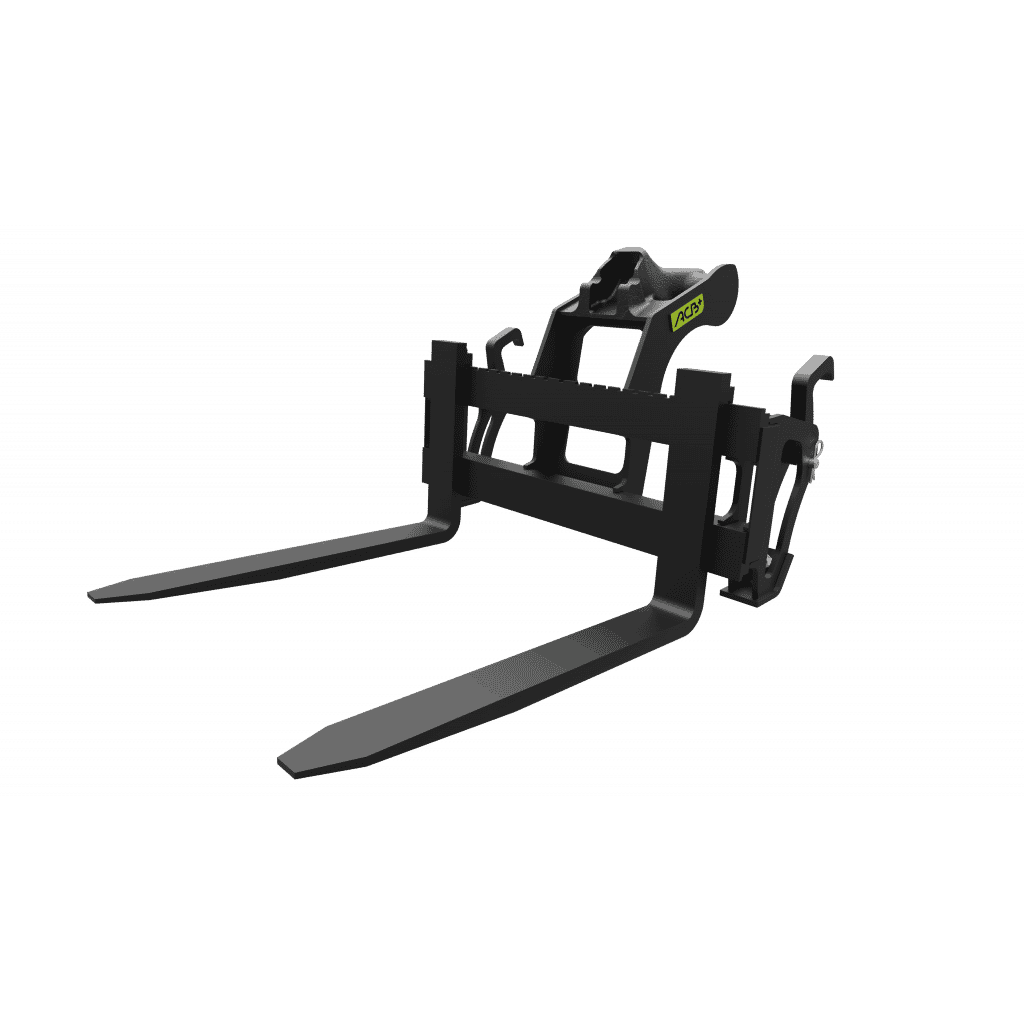

Pallet forks

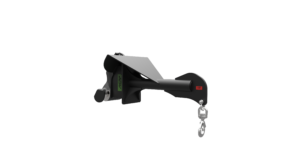

M2 to M7 Carriers from 3.5 to 35t

The pallet forks is a dedicated tool for the handling of pallets on the work site. Depending on the size of the machine, it can lift loads of 800, 1500 or 3000kg. We have several types of pallet forks which are standalone, to be installed or to be welded on the vehicle blade. This configuration with the blade allows the load to be handled while using the excavator arm to deposit the contents of the pallet.

Here are the two versions:

- A simple version, which allows the attachment by the quick coupler only. This product is called Pallet fork.

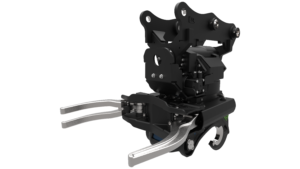

- A version with a predisposition on the front blade, allowing the user to hook the pallet lifter on its blade, for a use on construction site only.

Depending on the profile of the excavator blade, we are obliged to :

- Place the pallet fork on the blade with simple hooks: The pallet fork can then be moved laterally according to the needs of the construction site.

or - Fix the pallet fork with a predisposition to be welded on the blade: Welded pallet fork, the pallet fork remains then in a fixed position.

To order your pallet fork, you will have to specify us which version you wish knowing that for the second version, the option to be welded or to be fixed is dependent on the profile of the blade of your machine.

The forks are certified “lifting equipment” and their separation is adjustable on a frame with slide rails. Most of our forks have a pair of support legs for the deposited (down) position. The machine load table should be strictly respected, taking into account the offset and the weight of the pallet lifter. Additional valves are also required on the bucket actuator. The pallet forks must not be used with a tiltrotator, as their is a risk of tipping the pallet load at the first movement.