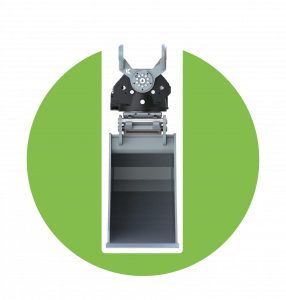

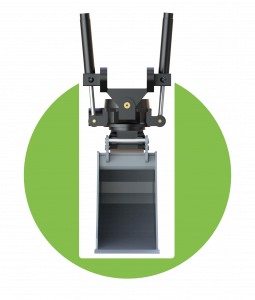

Hydraulic H2S tiltrotator

M2 For carriers from 3.5 t to 5.5 t

Compliant with standards EN474-1 and ISO13031:2016

As a major designer and manufacturer of tools and quick fasteners, ACB+ designs its couplers in the respect of the geometries imposed by the machine manufacturers. Thus, machine performance is entirely conserved.

The tiltrotator is a multi-function coupler, with 360° rotation and ± 50° inclination, that combines manoeuvrability with productivity. Available in hydraulic coupler version, and also mechanical (to order only).

Advantages of the hydraulic H2S tiltrotator nox inside in Morin Original System

- Multi-function coupler with 360° rotation and ± 50° inclination.

- Proportional control system for quick and precise working

- 2 hydraulic extra functions to control tools installed on the tiltrotator, through a revolving joint (standard equipment).

- Optional electrical revolving joint

- Low construction height, which limits the loss of digging force for all the tools mounted on the tiltrotator

- Compatible with all tools in Morin Original System and in original S and CW hookups

Description

Multi-function capability

The hydraulic H2S tiltrotator nox inside is the most complete coupler in terms of functions, and is used on hydraulic excavators from 3.5 to 5.5 tons.

The 360° rotation and the ± 50° inclination allow the tool mounted on the coupler to move in all directions simultaneously.

Our tiltrotator is proven and is extremely compact.

Unlike other tiltrotators on the market, the coupler has no protruding parts, thus allowing work in narrow trenches or in a forestry environment. This also reduces maintenance and the risk of breakage.

Inclination

The patented inclination function is based on an elliptical piston and a helical gear system to provide the inclination function. This design allows a low construction height, which limits the loss of digging force for all the tools mounted on the tiltrotator, with no external actuators.

| Tiltrotator with actuators | Tiltrotator nox inside without actuators |

|---|---|

|

|

| Actuators may be damaged by contact with earth, stones or branches | Narrow width, compact design, with robust construction |

| Bearing bushes need regular lubrication, which is additional maintenance | Little maintenance required, rotation elements in oil bath, few lubrication points |

| Inclination angle limited and loss of rotation torque as a function of the inclination angle | Constant torque inclination, with no loss of performance, irrespective of the inclination angle |

| Narrower width in the trench : on average, 120mm less (depending on the model) |

Orientation

The 360° orientation ring operates in a completely sealed oil bath, with no maintenance required for a long working life.

Construction

The tiltrotator has 2 integral hydraulic control functions for accessories. The hydraulic revolving joint is standard equipment and the electrical revolving joint is optional.

A fully integral tube gripper is also available as an option.

DF4 Control system

Control system DF4 needs two double action hydraulic circuits. Rotation and inclination can be executed simultaneously with the machine’s original proportional control system.

The DF4 cab control unit can divert the tilt function to:

- Up to two extra hydraulic functions, as selected, to feed hydraulic accessories

or

- the hydraulic quick hookup.

Machine requirements for DF4

- High rate auxiliary line with proportional control, to control inclination and the extra functions

- Medium rate auxiliary line with proportional control, to control rotation

- An ON/OFF button per extra function is required on the existing levers, to control their switching. If needed, ACB+ offers supplementary buttons as an option.

Compatibility:

The hydraulic H2S tiltrotator nox inside in the Morin Original System is suitable for mini-excavators from 3.5 to 5.5 tons. It is equipped with an integral lifting ring, designed to be used with the shackles recommended by ACB+ (except sandwich versions).

All the tools in the Morin Original system M2 can be used on the hydraulic H2S tiltrotator nox inside, which is pinned onto the machine with the original pins.

The tiltrotator nox inside is also available with the Nordic S and Verachtert CW systems.

Simple to use:

Only a few movements are needed to lock the tool. The same goes for unlocking; simply press the control unit in the cab to unhook the tool. In the case of a hydraulic problem, the powered hydraulic H2S tiltrotator nox inside can be unlocked using a standby key, thus providing service continuity.

Easy identification of module:

The module is easily identified through the use of a colour code on the casing and on the standby unlocking key. This advantage is particularly appreciated in multi-module installations.

The module ident. is also engraved the couplers and tools.

The powered hydraulic H2S tiltrotator nox inside is identified by the colour yellow.

Double SAFETY SYSTEM:

The hydraulic H2S tiltrotator nox inside is compliant with standards EN474-1 and ISO13031:2016

Like all the hydraulic couplers in the Morin Original system, the hydraulic H2S tiltrotator nox inside has a dual safety system, comprising a:

- Double-action hydraulic actuator, permanently pressurised, to hold the cam in the locked position

- Cam equipped with the patented Form-lock system that prevents any risk of accidental unlocking

The overall system is equipped with an indicator that is visible from the cab, to visually confirm proper locking.

Technical data

H2S Tiltrotator nox inside

| Characteristics of tiltrotator H2S TR07 DF4 | Value | Units | |

|---|---|---|---|

| Without tube gripper | With tube gripper | ||

| NOX MOTOR | TR07 | ||

| Type of tube gripper | – | TRG07 | |

| Weight of carrier vehicle | 3,5 à 5,5 | [t] | |

| Machine voltage | 12 | VDC | |

| Max. Break Out Force (BOF) ISO* | 50 | [kN] | |

| Max. bucket width | 1100 | [mm] | |

| Approx. weight | 260 | 310 | [Kg] |

| Rotation speed | 8 | [t/mn] | |

| Max. ROTATION pressure | 200 | [bar] | |

| Nominal ROTATION flow rate | 30 | [l/mn] | |

| Inclination pressure | 250 | [bar] | |

| Inclination flow rate | 15 | [l/mn] | |

| Inclination angle | +/- 50 | ° | |

| Number of lubrication points | 4 | 8 | |

| Max. lifting load on ring | 3 | [t] | |

* according to standard ISO6015:2006 Methods of determining tool forces

| Characteristics of extra functions depending on options | Connector (on coupler) (***) | Pmax | Nom. (*) – max. (**) flow rate | |

|---|---|---|---|---|

| Revolving joint

5 channels |

Channel A | 3/8″ – ND10 | 250 bar | 35 – 45 l/mn |

| Channel B | 3/8″ – ND10 | 250 bar | 35 – 45 l/mn | |

| Channel C (****) | 1/4″ – ND6 | 250 bar | 15 – 24 l/mn | |

| Channel D (****) | 1/4″ – ND6 | 250 bar | 15 – 24 l/mn | |

| Drain Channel (****) | 1/4″ – ND6 | 250 bar | 15 – 24 l/mn |

(*): nominal flow with 1.5 bar pressure drop

(**): maximum recommended flow rate

(***): Standard quick connector compliant with ISO 16028

(****): not available with tube gripper

Note: A tube gripper is optional on tiltrotators.

Connectors on the coupler are optional:

Without tube gripper: choice of

- 1 double-action line (channels A and B)

or

- 2 double-action lines + drain (channels A/B and C/D + drain)

(not available with tube gripper fed by channels C and D).