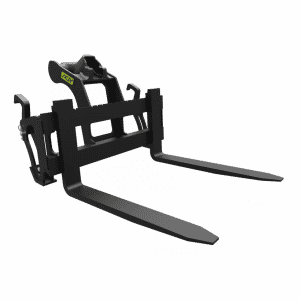

Mechanical tilt coupler M0S with power unit

M0 For carriers from 900kg to 2t

Compliant with standards EN474-1 and ISO13031:2016

As a major designer and manufacturer of tools and quick fasteners, ACB+ designs its couplers in the respect of the geometries imposed by the machine manufacturers. Thus, machine performance is entirely conserved.

Its very compact design (no protruding actuator or hoses) makes the ± 90° tilt power coupler perfect for working in small spaces. In addition, all moving parts are operating in an oil bath, which reduces maintenance work.

Advantages of the mechanical tilt coupler M0S with power unit

- Power-driven inclination ± 90°

- Power unit internal parts are operating in an oil bath, which reduces maintenance work.

- Extremely simple to installation, due to the use of an ancillary line for the inclination (proportional control strongly recommended)

- Coupler is compact for working in narrow trenches

- Compatible with all tools in Morin Original System the original S, CW and SW systems

Description

Functions: Maximum performance

The tilt power coupler is of narrow construction and is the ideal coupler for roads and networks working, and for creating and maintaining embankments. It will enable you to use smaller trenches and to access more extreme positions. The hydraulic power unit allows this coupler to provide ± 90° inclination at constant torque.

Reliability and compactness

The tilt mechanical power coupler M0S, with its hydraulic power unit, provides precision and strength for all your finishing work.

The patented inclination function is based on an elliptical piston and a helical gear system to provide the inclination.

Installation is easy and quick due to the use of a simple proportional ancillary line from the excavator.

To ensure that the inclination is maintained, a dual non-return valve may be installed as an option.

Easy maintenance:

All the power unit internal parts are operating in an oil bath, which reduces maintenance work..

The power unit assembly is protected by a casing, which is reassuring, particularly when working in narrow trenches.

The power unit is protected by robust mechanical stops at its travel limits.

Simple to use:

Only a few movements are needed to lock the tool. And similarly for unlocking. The smart key unhooks the coupler with a single action.

Easy identification of module:

The module is easily identified through the use of a colour code on the casing and on the standby unlocking key. This advantage is particularly appreciated in multi-module installations.

The module ident. is also engraved the couplers and tools.

The tilt mechanical power coupler M0S is identified by the colour white.

Compatibility:

The tilt mechanical power coupler M0S is suitable for mini-excavators from 900 kg to 2 tons. It is equipped with a lifting ring, designed to be used with the shackles recommended by ACB+.

All the tools in the Morin Original system M0, can be used with the tilt mechanical power coupler, which is pinned onto the machine with the original pins.

The tilt mechanical power coupler is also available with Nordic S, Verachtert CW and Liebherr SW original systems.

Double SAFETY SYSTEM:

The tilt mechanical power coupler M0S is compliant with standards EN474-1 and ISO13031:2016

Like all the mechanical couplers in the Morin Original system, the tit mechanical power coupler M0S has a dual safety system, comprising an

- Automatically activated stop that prevents any risk of cam backward movement – patented system

- Cam equipped with the patented Form-lock system that prevents any risk of unlocking if the safety stop fails

The overall system is equipped with an indicator that is visible from the cab, to visually confirm proper locking.

Technical data

Mechanical tilt coupler M0S with power unit

| Specification | Value | Units |

|---|---|---|

| Inclination power unit | RA02-180 | |

| Weight of carrier vehicle | 1 à 2 | [t] |

| Max. Break Out Force (BOF) ISO* | 19 | [kN] |

| Max. bucket width | 1000 | [mm] |

| Approx. weight | 47 | [Kg] |

| Max. inclination pressure | 250 | [bar] |

| Inclination flow rate | 8 | [l/mn] |

| Inclination angle | 190 | ° |

| Number of lubrication points | 5 | |

| Max. lifting load on ring | 1 | [t] |

Option: Dual inclination support valve – highly recommended if the machine ancillary line leaks.

* according to standard ISO6015:2006 Methods of determining tool forces