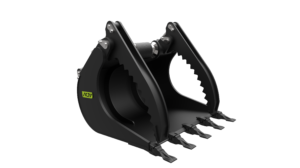

Mechanical M1S and hydraulic H1S ROTO+ rotating coupler

M1 For carriers from 2t to 3.5t

Compliant with standards EN474-1 and ISO13031:2016

As a major designer and manufacturer of tools and quick fasteners, ACB+ designs its couplers in the respect of the geometries imposed by the machine manufacturers. Thus, machine performance is entirely conserved.

The orientable coupler has a broad range of applications. It provides a multi-function capability and the reversibility of all compatible tools.

Using the 360° rotation, do up to 80% of the work of a tilt-rotator for a much lower cost. The orientation function is available in a mechanical or hydraulic coupler version and allows very precise working, particularly for roads and networks.

- 360° rotation through the hydraulic power unit, and the wheel and worm gear.

- Hydraulic (on option for the Module 2 mechanical coupler) and electrical (option) revolving joints are available to accept all types of tools.

- Extremely simple to install due to the use of an ancillary line for the rotation (proportional control strongly recommended)

- Oversized crown for occasional use of a HBR

- Sealed casing for total protection of the hydraulics.

- Rotation sensor for optional integrated 2D/3D guidance system

- Compatible with all tools in Morin Original System, CW Verachtert, the original S and SW original Liebherr hookup systems

Description

Functions:

An orientable coupler offers many more possibilities than a tilting coupler.

Compared to a tiltrotator, it allows you to do more than 80% of the work done with a tiltrotator with real advantages in performance, driveability and machine integration. Less heavy, more compact, more hydraulic flow, easier to install, more economical, the rotating solution has real advantages.

Compared to a tilting coupler, it gives you more mobility but also the precision required for applications such as roadwork, embankments of complex shapes, trench filling, mounding and riprap work, pallet handling and finishing work around obstacles.

Compared to a conventional coupler, it saves you 10% in excavation, 30% in roadwork and 50% in landscaping, simply because you can go into the smallest details of finishing your work.

- The reversibility of your tool in half a turn: without removing your tool, it goes in a few seconds from a use in back to a use in mound.

- A rotation that tilts the bucket: thanks to the combination of the rotation, the bucket kinematics and the swivel coupler, you can carry out all your embankment and trench filling work.

The orientable coupler is the perfect solution to the versatility requirements of your work sites.

Indeed, it allows a wider range of use than the tiltable couplers and brings you the precision required for applications in public works: embankment of complex shapes, dumping and filling of trenches, mounding work, riprap, moving a pallet, working around a pipe, sorting, compaction, hydraulic hammer …

Manoeuvrable and practical :

Driver familiarisation with the mechanical M1S and hydraulic H1S ROTO+ orientable couplers is simple and quick due to their compact design and their driving through a single hydraulic function in the cab.

Equipped with a worm and wheel coupling for high precision and 360° rotation.

No complex conversion or extra equipment is required to install the mechanical M1S or hydraulic H1S ROTO+ orientable coupler. Most machines have 2 auxiliary lines and the line with the highest flow rate is kept to feed tools such as the HRB.

In fact, the HRB can be used occasionally, thus avoiding sandwich assemblies.

The mechanical M1S ROTO+ R04 orientable coupler can, on option, be equipped with a hydraulic revolving joint, the flow rates of which allow a hammer or a gripper to be used (standard for hydraulic coupler H1S) and, again on option, an electrical connection.

In order to assist you in your choice of equipment, the ROTO+ R04 orientable coupler in its mechanical M1S and hydraulic H1S versions can be equipped with a 2D/3D sensor compatible with the main manufacturers of guidance systems. (TOPCON, TRIMBLE, LEICA, IDIG)

Reliability:

The ROTO+ R04 mechanical M1S and hydraulic H1S orientable coupler complies with EN474-1 and ISO13031:2016 standards.

It is equipped with a worm and wheel coupling specifically designed and dimensioned by our development department, and protected by a high resistance steel monobloc housing, entirely sealed for a longer life. The components are carefully selected for their mechanical strength and resistance to wear.

The oversized crown of the ROTO+ R04 orientable coupler and the optimal arrangement of the components allow the occasional use of a hydraulic hammer.

Simple to use:

Only a few movements are needed to lock the tool.

For the mechanical coupler M1S : Unlocking with the smart key unhooks the tool with a single action.

For the hydraulic coupler H1S : Unlocking by simply pressing the control unit in the cab unhooks the tool. In the case of a hydraulic problem, the H1S coupler can be unlocked using a standby key, thus providing service continuity.

Easy identification of module:

The module is easily identified through the use of a colour code on the casing and on the standby unlocking key. This advantage is particularly appreciated in multi-module installations.

The module ident. is also engraved the couplers and tools.

The mechanical M1S and hydraulic H1S rotating couplers are identified by the colour red.

Compatibility:

The mechanical M1S and hydraulic H1S ROTO+ R04 orientable coupler is suitable for mini-excavators from 2 to 3.5 tons. It is equipped with a lifting ring, designed to be used with the shackles recommended by ACB+.

All the tools in the Morin Original system M1, can be used with the mechanical M1S and hydraulic H1S ROTO+ R04 orientable coupler, which is pinned onto the machine with the original pins.

The mechanical M1S rotating coupler is available with the Morin Original system and in the CW Veractert system, the Nordic S and SW original Liebherr.

It is also compatible with most 2D/3D guidance systems. A rotation sensor can be integrated in order to benefit from this over-equipment.

To benefit from a perfect rotation, the Universal ditch cleaning bucket has been developed. Its bevelled sides avoid the heel during excavations and optimize the rotation, for passages as close as possible to the obstacles.

For specific applications, a BRH can be used on the ROTO+ R04 orientable coupler.

Double SAFETY SYSTEM:

The mechanical M1S and hydraulic H1S ROTO+ R04 orientable coupler is compliant with standards EN474-1 and ISO13031:2016

Like all the mechanical couplers in the Morin Original system, the mechanical M1S ROTO+ rotating R04 coupler has a dual safety system comprising an

- Automatically activated stop that prevents any risk of cam backward movement – patented system

- Cam equipped with the patented Form-lock system that prevents any risk of unlocking if the safety stop fails

Like all the hydraulic couplers in the Morin Original system, the hydraulic H1S ROTO+ rotating R04 coupler has a dual safety system comprising an

- Double-action hydraulic actuator, permanently pressurised, to hold the cam in the locked position

- Cam equipped with the patented Form-lock system that prevents any risk of accidental unlocking

The overall system is equipped with an indicator that is visible from the cab, to visually confirm proper locking.

Don’t wait any longer and contact us now to learn more about our ROTO+ orientable coupler and how it can help you gain efficiency and productivity. Contact

Technical data

Mechanical M1S and Hydraulic H1S ROTO+ R04 rotating coupler

| COUPLERS | M1S Mechanical | H1S Hydraulic | Units | |

|---|---|---|---|---|

| ROTO+ | R04-360 | |||

| Weight of carrier vehicle | 2 à 3.5 | [t] | ||

| Max. Break Out Force | 21.5 | [kN.m] | ||

| Max. digging force. | 32 | |||

| Max. bucket width | 1000 | [mm] | ||

| Weight (Approx.) | Mechanical coupler With/without rotating joint | 87 / 93 | [Kg] | |

| Hydraulic coupler | 100 | |||

| Rotation Speed: | With proportional control | 9 | [t/mn] | |

| With On/Off control | 5 | |||

| Max. pressure ROTATION | 140 (**) | [bar] | ||

| Nominal flow rate ROTATION | With proportional control | 16 | [l/mn] | |

| With On/Off control | 9 | |||

| Number of lubrication points

(crown/coupler) |

Mechanical coupler | 4/3 | ||

| Hydraulic coupler | 4/2 | |||

| Max. clearance at rotating joint | 1.3 | [mm] | ||

| HYDRAULIC DATA OF THE ROTATING JOINT (optional with mechanical couplers) | ||||

| Tracks 1 et 2 : (Tools feed) | Pmax | 250 | [bars] | |

| Max. flow rate | 45 | [l/mn] | ||

| Male connector | 3/8’’ – DN10 – ISO 16028 With pressure elimination | – | ||

| Tracks 3 et 4 | Not assignable on mechanical couplers – reserved for locking on hydraulic couplers | |||

| Tracks 5 : Drain | Pmax | Not available | [bars] | |

| Max. flow rate | [l/mn] | |||

| Male connector | – | |||

| Electric rotating joint | Optional – 12 tracks – consult us | |||

| Pre-equipment for guidance system 2D/3D | Compatible with systems TRIMBLE -LEICA – TOPCON – IDIG | |||

* according to standard ISO6015:2006 Methods of determining tool forces

(**) : integrated limiter as standard | (***) : external limiter available as an option

Note : The presence of a rotating joint is optional on the ROTO+ mechanical coupler M1S. The above data concerning the rotating joints therefore depend on the configuration of your rotating coupler.

The pressures given are the maximum permissible pressures on the rotating joint tracks. They must be adapted to the pressures of the quick couplers located under the orientation system. Please refer to the specific manual of the coupler.